Faced with completely different building specifications, market demands and industry ecology, is it feasible for prefabricated and assembled buildings to go overseas? Space-o Boundary Technology Group, a domestic one-stop delivery company for green prefabricated buildings, will deeply analyze for you: how to cross the standard barriers, adapt to market characteristics, build a bond of trust, and realize the overseas implementation of prefabricated and assembled building solutions.

Space-o Boundary Technology Group Australian Housing Project Case

1. Australia and New Zealand Market: "New Blue Ocean" with both opportunities and challenges

Chinese construction companies have shown the potential of "dimensionality reduction" in entering the Australian and New Zealand markets, but also face the challenge of "not adapting to the local environment".

1. The competitive advantage of “dimensionality reduction attack”(1) The driving force behind the surge in demand for Chinese prefabricated buildings in the Australian and New Zealand markets

Housing shortage crisis: Australia plans to build 1.2 million new homes within five years, and New Zealand faces a gap of 100,000 homes. Local construction companies are unable to meet such a huge demand. The scale production benefits brought by China's huge manufacturing base can provide more sufficient production capacity support for the Australian and New Zealand markets, thereby meeting the urgent demand for housing construction in the local market.

(2) Scale and efficiency advantagesThe scaled production benefits, mature and complete supply chain system and technical capabilities brought by China's huge manufacturing base, as well as the relatively low labor cost advantage, further highlight and strengthen the advantages of prefabricated buildings in saving construction time, reducing costs and green and low-carbon. This "dimensionality reduction" competitive advantage formed by the superposition of multiple advantages makes China's prefabricated buildings more competitive in the international market.

Space-o Boundary Technology Group Australian Housing Project Case

2. The core pain point of “not acclimatized”

(1) Market standard barriers: Chinese standards vs. Australian and New Zealand standardsGiven the significant differences in standards for building fire protection, earthquake resistance, and environmental protection among countries, products that have not obtained corresponding certification will not be able to meet the acceptance requirements of the importing country. Due to the incompatibility of the standard system, some construction companies will directly lose their overseas market access qualifications.

(2) Cost considerations: low price advantage vs. hidden costs

For Australian housing projects, although purchasing prefabricated buildings from China has the obvious advantage of low-cost purchase price and can also save labor costs, the hidden costs involved in cross-border procurement, such as logistics, tariffs, installation and commissioning, cannot be ignored. Under comprehensive cost comparison, it is not clear at a glance which one is better.

(3) Market competition and brand recognition

After a long period of accumulated brand reputation, local enterprises have occupied a significant market share. For prefabricated construction companies from China, the long-term accumulated trust of local enterprises among owners is difficult to break through.

2. Lessons from Space-o Boundary Technology's Australian House Building Case: Breaking the Cross-Border Road of Prefabricated Buildings

Prefabricated buildings going overseas is not a simple output of production capacity, but a multi-dimensional ecological reconstruction of technology, standards and services, building a full-chain capability for prefabricated buildings going overseas. Through large-scale production, the Space-o-Boundary Australian housing project has achieved a lower overall cost than the local solution and a shorter construction period, providing more options for Australian housing construction.

1. Compliance first: from "Made in China" to "Global Adaptation"

As a global one-stop delivery service provider for green wood structure assembled houses, Space-o Technology Group mainly serves the markets of China, North America, Australia and New Zealand, Japan and South Korea, Europe, the Middle East, and other Southeast Asian regions. It has more than 10 residential product certifications and delivery certifications in developed countries, as well as overseas construction and house construction certifications.

2. Technology leadership: dual drive of digitalization and intelligence

Digital empowerment: Data asset barriers: accumulated 12,000+ design solution databases; trained the industry AI vertical industry model ZERO-MEGA, and increased solution generation efficiency by 17 times;

Smart factory construction: Relying on the self-developed and introduced wooden house production line automation equipment, fully automatic servo finger joint connection line and other highly intelligent equipment and intelligent management systems such as ERP and MES, Space-o Technology Group has realized the automation, informatization and intelligent management of the production process, and the on-time delivery rate of orders can be increased to 98%.

Space-o Technology Group Green Wall Components for Prefabricated Wood Structure Buildings

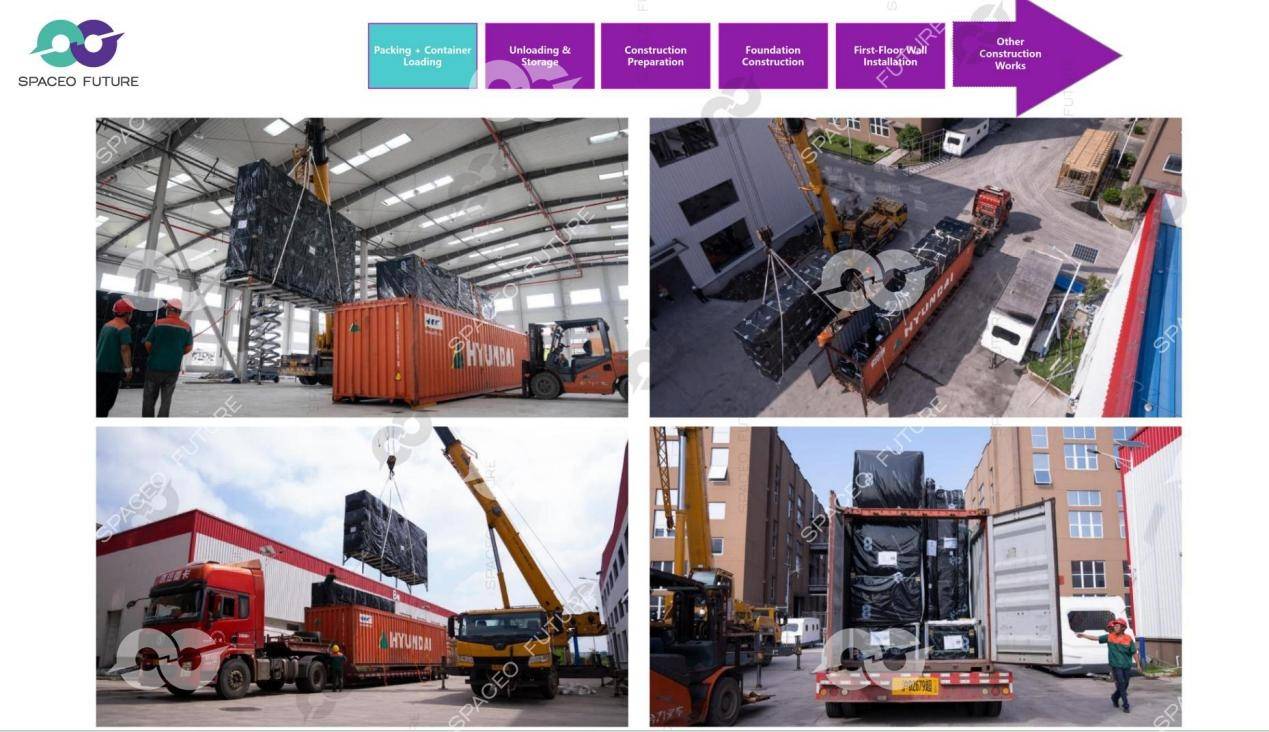

3. Global service: quick response and efficient delivery

By establishing a 6S service center, Space-o Boundary Technology Group has set up pre-sales consultation, design, production, logistics, installation, and after-sales service nodes in Australia, achieving "72 hours of drawing + 45 Days Delivery", providing Australian customers with a one-stop solution, shortening the project cycle by several months, while reducing communication costs.

4. Cost strategy: reject low-price competition and create full-cycle value

Space-o Technology Group is well aware that low-price competition is not a long-term solution. Therefore, Space-o has achieved effective control of comprehensive costs by providing high-quality products and services, optimizing supply chain management, and reducing hidden costs. This cost strategy with "full-cycle value" as the core has not only improved Space-o's profitability, but also enhanced Space-o's competitiveness in the international market.

Space-oBoundary Technology: A reliable partner in the Australian housing market

As a global one-stop delivery service provider of green wooden structure assembled houses integrating technology + software tools + supply chain + manufacturing + services, Space-o Technology Group has now opened up the design-manufacturing-logistics-construction data flow, which has increased cross-enterprise collaboration efficiency by 10 times and reduced costs by 30%, opening up channels for China's excess production capacity to go overseas. If you are looking for a reliable prefabricated building supplier, please contact Space-o Technology Group to obtain customized Australian house building solutions and unlock new opportunities for prefabricated buildings to go overseas!

400-999-1817

400-999-1817 Current Location:

Current Location:

2024.04.30

2024.04.30